Hardfacing steel plate

Category:

Description

Wear-resistant steel plate serious

| Model |

HRC |

Working |

Alloy chemcial composition |

Specification and thickness |

||||

|

C |

Cr |

Mn |

Nb |

Others |

||||

|

HP100 |

60-63 |

>500℃ |

3-5 |

22-28 |

|

|

48 |

4+4、5+5、6+5、6+6、8+5、8+6、8+8、10+5、10+6、10+7、 |

|

HP200 |

58-62 |

>500℃ |

3-5 |

20-26 |

1-3 |

|

2-5 |

|

|

HP300 |

60-65 |

>800℃ |

4-6 |

18-25 |

2-3 |

5-8 |

3-6 |

|

|

HP400 |

50-55 |

>500℃ |

0.4-2 |

3-7 |

15-20 |

|

2-5 |

|

|

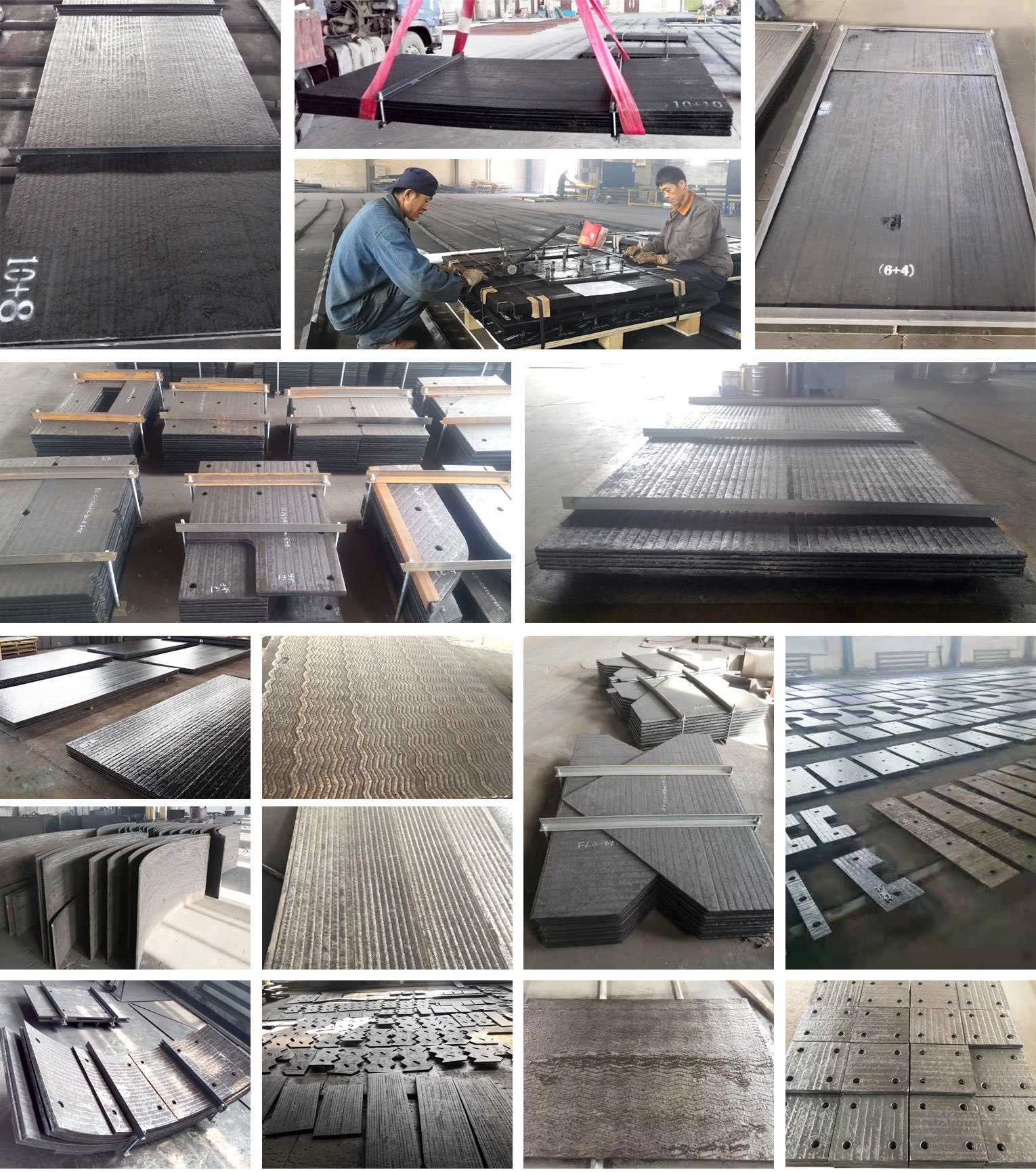

Industry |

Power industry |

Coal hopper lining plate, coal drop pipe liners, coal mill wear parts, ash pipeline, fan blade |

||||||

|

Iron and steel industry |

Bin liner, skip car liner, vibrating feeder lining, CDQ tank lining, coke-barrier car bottom plate, slag sluice lining |

|||||||

|

Cement industry |

Raw mill lining, clinker chute lining, dust discharge pipe, guide vane, roller protection sleeve, slag mill wear parts |

|||||||

|

Glass industry |

Blender mixer bottom plate, fan blade, fore and rear discs of fan impeller, quick-wearing wear parts |

|||||||

|

Mining industry |

Excavator bucket liners, bucket-wheel excavator, scarper conveyer middle trough, elevator skip, hopper liner |

|||||||

|

Engineering machinery |

Shield machine wear parts, boring machine shovel plate, loader shovel plate, dump truck body plate. |

|||||||

| Port | Loading and discharging machine, wear-resistant pipeline, channel dredging, bin liner | |||||||

|

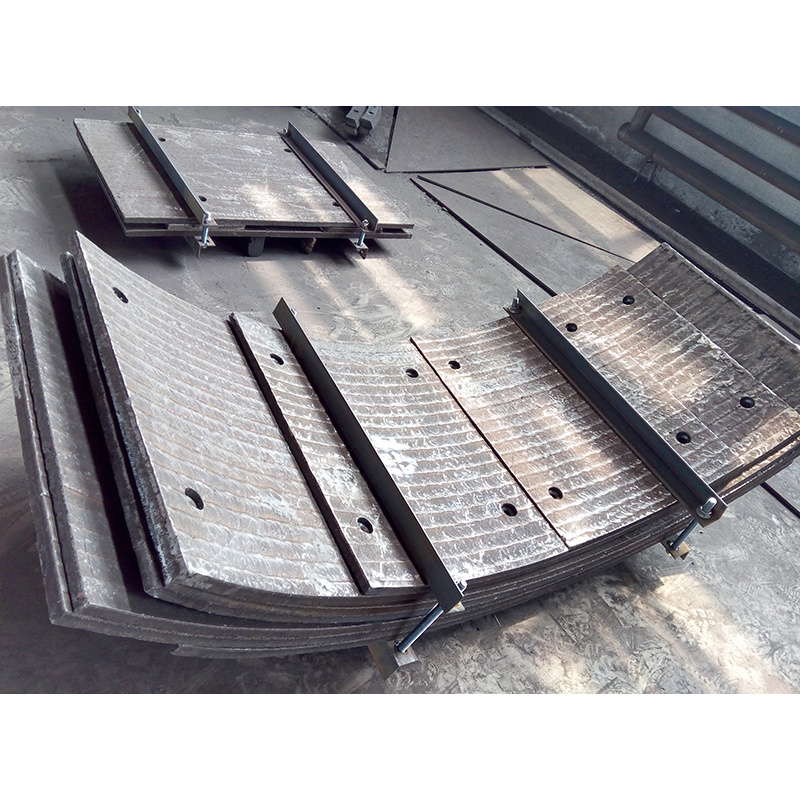

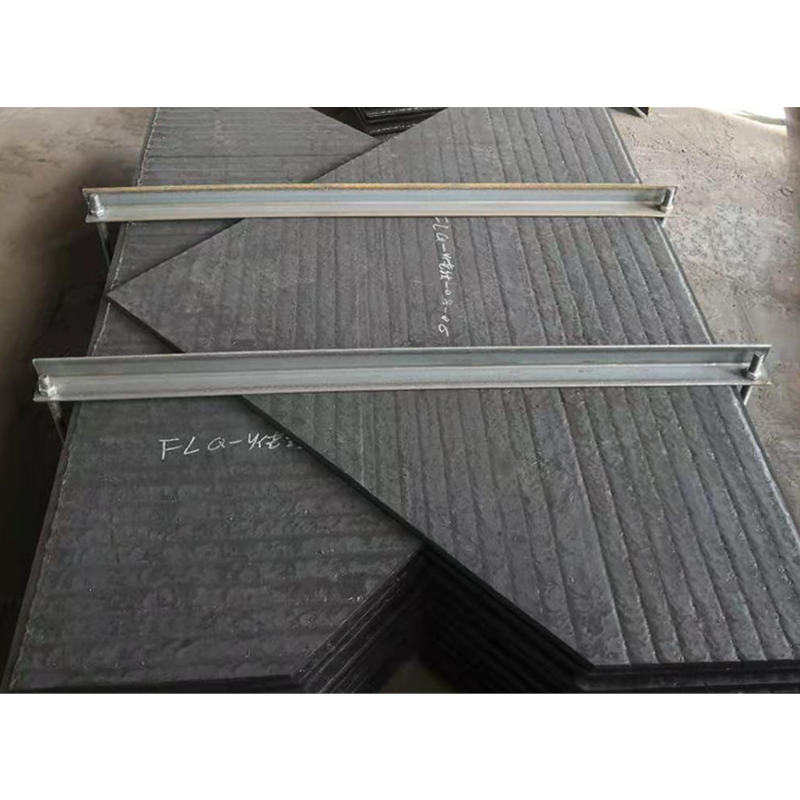

We also customize various specificaion wear-resistant plate and wear parts according to customer requirement and drawings. |

||||||||

Processability

• Cutting: Plasma cutting, carbon arc, grinding wheel saw can be used to cut large area Javier hard surface wear-resistant steel plate into the required shape.

• Bending: Havel hard face wear-resistant steel can be cold-processed and bent into the desired shape, arc or circle, as needed.

• Opening: Plasma cutting can be used for large holes, and point spark machine tools are recommended for small holes. Countersunk holes for bolt assembly can be cut by plasma or carbon arc.

• Welding: The substrate of Havel hard face wear-resistant steel plate is a low carbon steel plate with good weldability. When two steel plates need to be joined, the back substrate can be welded together first, and then the front surfacing layer can be filled with the corresponding hard face wear-resistant welding rod. Hard-faced wear-resistant steel plates can also be welded to other steel structures.

• Plug welding: Plasma or carbon arc gouging can be used to cut holes in Javier hard surface wear-resistant steel plates, and connect with other steel structural parts by plug welding.

• Bolt fixation: The bolts can be welded to the substrate of the wear-resistant steel plate by flash welding or melt welding, and then connected to other workpieces, or the wear-resistant steel plate can be cut and connected to other workpieces by bolts.

• Surface processing: Havel hard surface wear-resistant steel plate surface generally do not need processing, if you want to process, processing is limited to grinding.

• The use of welding rods and wires: the construction site often needs to use welding rods and wires to fill installation gaps, strengthen and repair severely worn parts. Javier offers the Javier series of wear-resistant surfacing rods and wires.

Compared with many wear-resistant materials, wear-resistant composite steel plate has its irreplaceable significant characteristics:

1. Surfacing wear-resistant plate; High wear resistance

The chemical composition of the alloy layer contains 4~6% carbon and 25~30% chromium. The volume fraction of Cr7C3 carbide in the metallographic structure is greater than 45%, and the macroscopic hardness is HRC56~62. The hardness of chromium carbide is between HV1400 and 1800, which is higher than the hardness of sand and stone. Due to the vertical distribution of carbides along the wear direction, the wear resistance is more than doubled compared to cast alloys with the same composition and hardness. Compared with several typical materials, the wear resistance is as follows:

(1) With low carbon steel: 20~25;

(2) With high manganese steel: 5~10;

(3) Tool steel: 5~10;

(4) Cast high chromium cast iron: 1.5~2.5.

2. Surfacing wear-resistant plate: good impact resistance

The bottom layer of wear-resistant composite steel plate is low carbon steel or low alloy. Ductile materials such as stainless steel show the superiority of bimetal. The wear-resistant layer resists the wear of the wear medium, and the matrix bears the load of the medium, so it has good impact resistance. It can withstand the impact and wear of the high drop hopper in the material handling system.

3. Surfacing wear-resistant plate: good heat resistance

The wear layer is recommended when the temperature is ≤600 ° C. If the alloy layer is added to vanadium, molybdenum and other alloys, it can withstand high temperature wear ≤800℃. The recommended temperature is as follows: The recommended temperature for ordinary carbon steel substrate is not higher than 380 ° C; Low alloy heat resistant steel plate (15CrMo, 12Cr1MoV, etc.) The base is recommended for use at a temperature not higher than 540 ° C. It is recommended to use heat-resistant stainless steel substrates at temperatures not higher than 800 ° C.

4. The alloy layer of the composite steel plate with good corrosion and wear resistance contains a high proportion of metal chromium, so it has a certain rust and corrosion resistance. Can be used in coal trough and funnel to prevent coal sticking.

5. Strong applicability

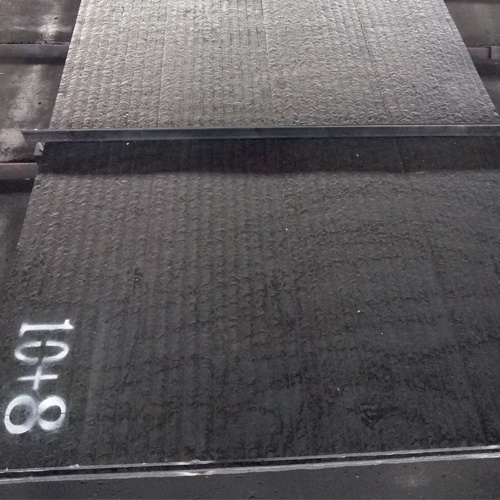

Wear-resistant composite steel sheet with complete specifications and wide varieties has become a series of commodities. The thickness of the wear-resistant alloy layer is 3 ~ 20 mm, the minimum thickness of the composite steel plate is 6mm, and the thickness is not limited. The standard wear-resistant composite steel plate can be provided with 1200 or 1450×2000mm, and can also be customized according to the drawing size according to user requirements. Wear-resistant composite steel plates are now divided into three types: ordinary type, impact resistant type and high temperature resistant type. Order high temperature wear and impact resistant composite steel plate should be stated.

6. Easy processing

Wear-resistant composite steel plate can be cut, levelled, punched, bent, crimped, can be made into flat plate, curved plate, conical plate, cylinder. The cut composite board can be welded into various engineering structures or parts. Composite plates can also be heated and pressed into complex shapes by a mold. Wear-resistant composite steel plates can be bolted or welded to the equipment for easy replacement and maintenance.

7. High cost performance

Although the manufacturing cost of wear-resistant composite steel plate has been increased, the service life has been increased several times, greatly reducing the maintenance cost and shutdown loss, and its cost-effective ratio is about 2 to 4 times higher than that of ordinary materials. The greater the material processing capacity, the more serious the equipment wear, the more obvious the economic effect of using wear-resistant composite steel plate.

Product inquiry