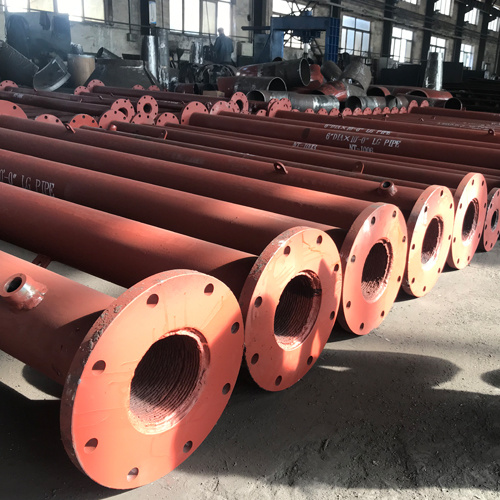

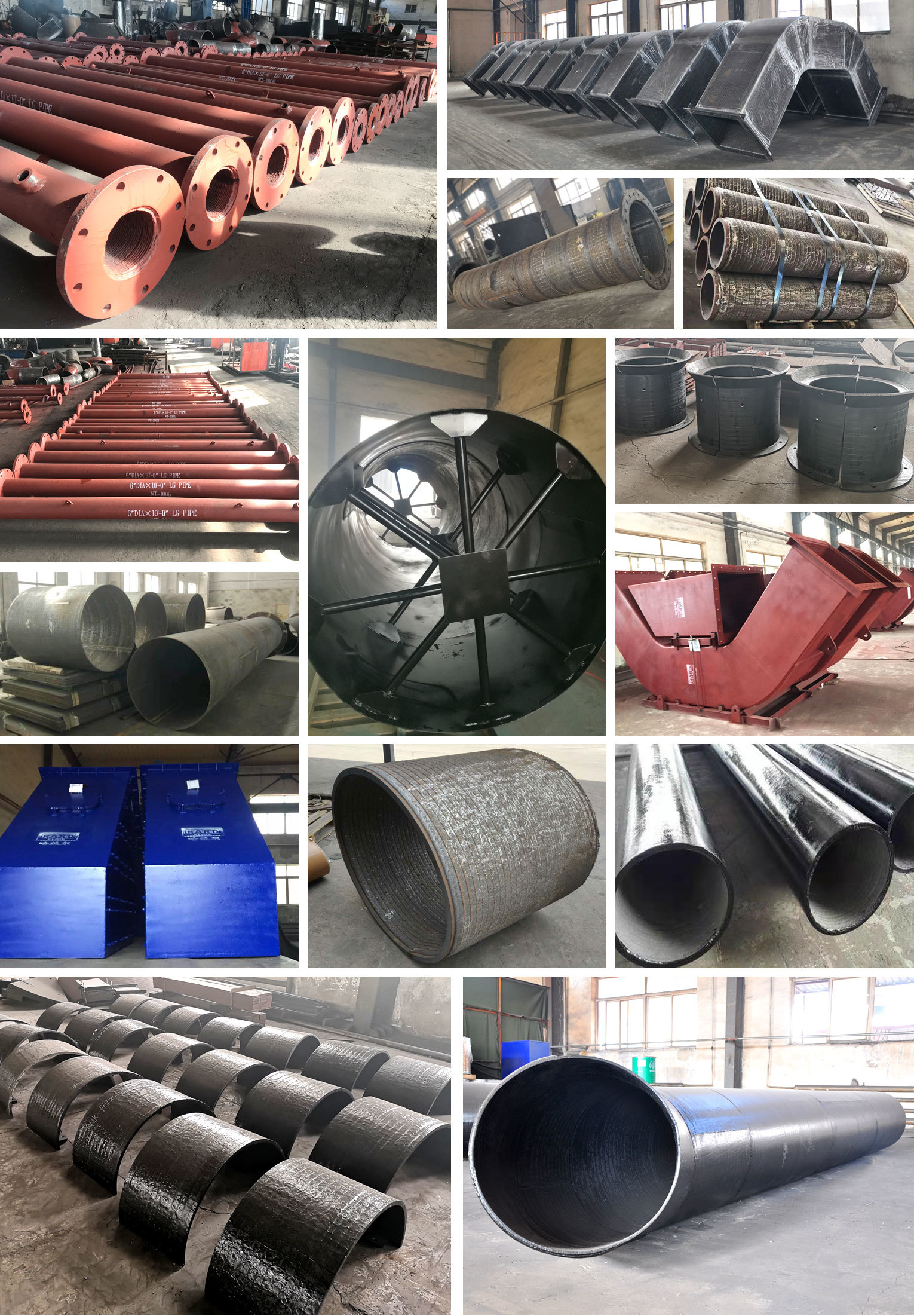

Hardfacing pipelines and elbows

Category:

Description

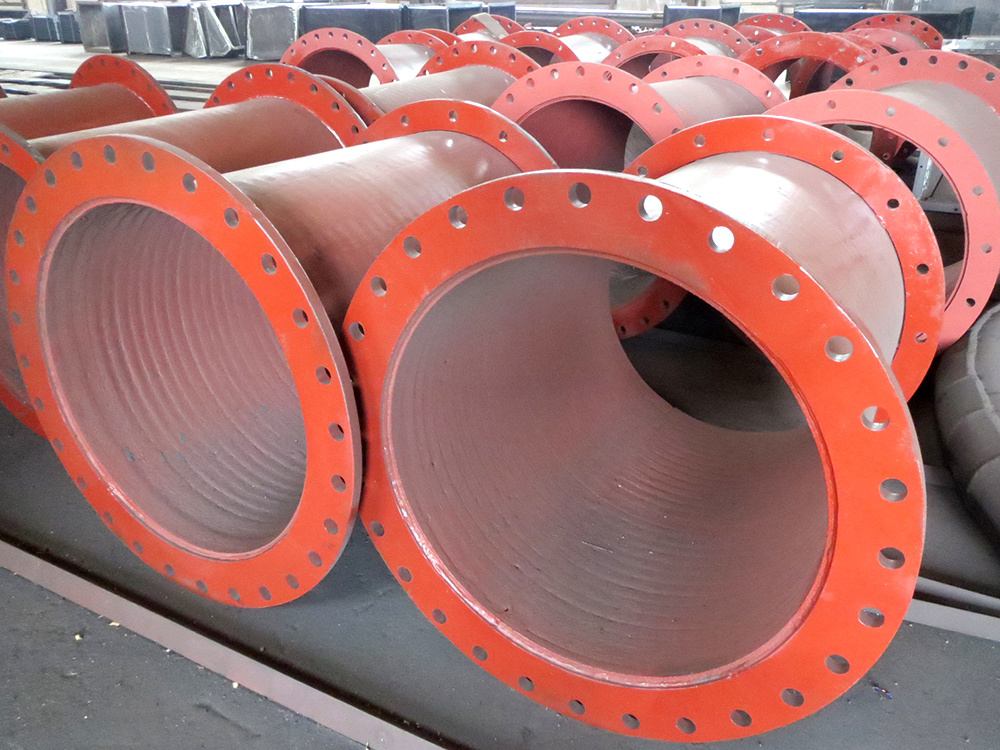

The wear-resistant pipe is composed of wear-resistant substrate and wear-resistant layer, and the wear-resistant layer generally accounts for 1/3-2/3 of the total thickness of the pipe.

Between the wear-resistant layer and the substrate is metallurgical bonding, the wear-resistant layer will not fall off and can withstand greater impact;

Wear-resistant pipes are processed by wear-resistant steel rolling and direct surfacing welding in seamless pipes.

The performance of the wear-resistant layer formed by surfacing welding in the tube is the same as that of the wear-resistant steel plate.

Wear-resistant pipe connection method for flange connection and welding connection two methods;

Wear-resistant pipes can be processed into elbows, tees, round places, cone tables, square pipes, etc.

Product inquiry